Taian Haishu Machinery Co.,Ltd.

Telephone: +86-538-8606169

Fax: +86-538-8606169

Address: Zhouwangzhuang Village, Shankou Town

Taian City Shandong Province China

The prevention of CNC lathe cutting tools directly determines its processing efficiency.

The prevention of CNC lathe cutting tools directly determines its processing efficiency. For the operation of CNC lathes, the installation and loading/unloading of cutting tools is one of the important steps. It not only affects the efficiency of the lathe

For the operation of CNC lathes, the installation and loading/unloading of cutting tools is one of the important steps. It not only affects the efficiency of the lathe For the operation of CNC lathes, what we care about is the use of cutting tools, which have very high requirements in terms of cutting efficiency and tool replacement speed.

For the operation of CNC lathes, what we care about is the use of cutting tools, which have very high requirements in terms of cutting efficiency and tool replacement speed. We all know that a CNC lathe is a system composed of many devices, and there are subtle changes in the arrangement of these systems.

We all know that a CNC lathe is a system composed of many devices, and there are subtle changes in the arrangement of these systems. For the operation of CNC milling machines, the radial runout of cutting tools is a significant issue. Radial runout not only has a significant impact on machining accuracy

For the operation of CNC milling machines, the radial runout of cutting tools is a significant issue. Radial runout not only has a significant impact on machining accuracy During the operation of CNC lathes, pitch deviation sometimes occurs, which is also accepted in the industry. However, pitch deviation also has certain requirements.

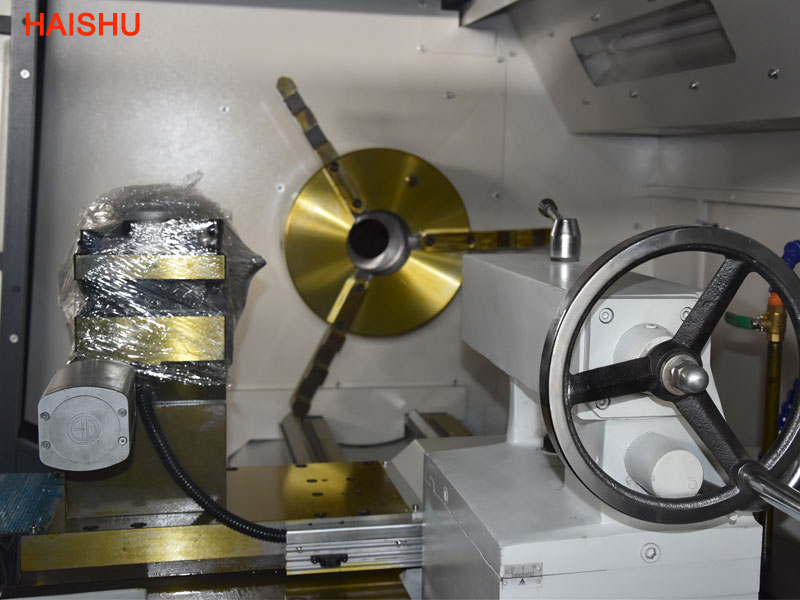

During the operation of CNC lathes, pitch deviation sometimes occurs, which is also accepted in the industry. However, pitch deviation also has certain requirements. Chuck stall is a common fault in CNC lathe machining and the main cause of machining accuracy errors. Therefore, we must strictly control the speed and stability of the chuck.

Chuck stall is a common fault in CNC lathe machining and the main cause of machining accuracy errors. Therefore, we must strictly control the speed and stability of the chuck. During the operation of a CNC lathe, tool loading is a very common and important task. The speed of tool loading not only has a certain impact on machining efficiency but also on the service life of the lathe.

During the operation of a CNC lathe, tool loading is a very common and important task. The speed of tool loading not only has a certain impact on machining efficiency but also on the service life of the lathe.

Bearings play a very important role in the configuration of CNC lathes. They play an irreplaceable role in force transmission and changing the direction of force.

Bearings play a very important role in the configuration of CNC lathes. They play an irreplaceable role in force transmission and changing the direction of force. Before starting the operation of the CNC lathe, a series of initial data debugging needs to be done. The purpose of this is first to set the basic data required for machining operation.

Before starting the operation of the CNC lathe, a series of initial data debugging needs to be done. The purpose of this is first to set the basic data required for machining operation. Programming method occupies a very important position in CNC lathe pitch processing. For pitch processing, the error value requirements for the transmission screw are very strict and must be within a certain control range.

Programming method occupies a very important position in CNC lathe pitch processing. For pitch processing, the error value requirements for the transmission screw are very strict and must be within a certain control range. In the field of CNC lathe programming, there is often a legendary existence. Having a good machine is not as good as having a good set of programming.

In the field of CNC lathe programming, there is often a legendary existence. Having a good machine is not as good as having a good set of programming.CNC lathe research and development, every problem we can not be ignored!

How to make my machine have a longer service life?

How to make the equipment have higher production efficiency?

How to ensure that the machine is simple to learn?

... ...

Learn CNC lathes

From the beginning our website!

Global Service Hotline:+86-0538-8606169